Alberta's investment in carbon capture technology not worth bang for buck, environmental group argues

A new report accuses the oil-and-gas industry of greenwashing the impact of carbon capture and storage – also known as CCS – technology, pointing to an oil-processing complex in Alberta that emits more carbon than it buries in the ground.

The report by Global Witness argues CCS is a poor substitute for phasing out fossil fuels and an expensive undertaking that the governments of Alberta and Canada partly funded.

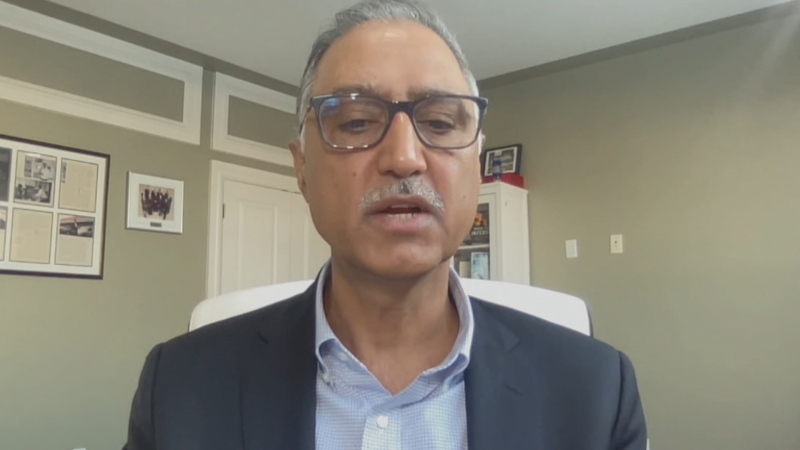

"We think this really isn't sustainable, it's not climate friendly, and it shows that governments across the world, not just in Canada, mustn't support fossil hydrogen," report author Dominic Eagleton told CTV News Edmonton. "They should boost more genuinely sustainable alternatives to fossil hydrogen, such as renewables."

Global Witness, a non-government organization based in the U.K., says its goal is to create a "more sustainable, just and equal planet."

Eagleton, a senior campaigner with the group, compared the amount of emissions produced at Shell's Scotford Complex in Fort Saskatchewan, northeast of Edmonton, with the amount of carbon dioxide its CCS system – called Quest – removes. He says the site was chosen because of the data publicly available on it.

Global Witness found that between 2014 and 2019, Quest stored five million tonnes of carbon dioxide, or CO2. During the same period, it says the Scotford Complex produced in total 7.5 million tonnes of greenhouse gases, including methane. The data was pulled from reports submitted by Shell to the Alberta government, as well as data crunched by the Pembina Institute.

Eagleton calls the 2.5-million tonne difference a "wake-up call for the world."

Shell believes Quest hints at what is possible in the future.

'A DEMONSTRATION PROJECT'

Shell operates Quest on behalf of its partners mining oil sands in northern Alberta and refutes Global Witness' assertion it overpromised Quest's potential.

In addition to the CCS system, Scotford Complex consists of an upgrader that turns bitumen from those oil sands into lighter crude products, a refinery that makes fuels and other products from synthetic crude oil, and a chemical plant.

In order to upgrade bitumen, Shell makes hydrogen, producing carbon dioxide in the process.

Quest's job is to capture and liquefy CO2 before trapping it two kilometres below ground.

Quest has stored about six million tonnes of carbon in its six-and-a-half years – faster and cheaper than expected, according to the company. However, the system was never meant to capture more than one third of the Scotford upgrader's emissions, Shell maintains.

When Quest was built, it was touted as the world's first commercial-scale CCS facility at an oil sands operation. And, as one of the first facilities of its kind, Quest isn't able to capture and store as much carbon as is now possible – around 90 per cent, the industry estimates.

"We were there working with the government to really demonstrate Quest as a proof point that CCS does work. Not only in the capture in a brownfield site, but also the storage complex," Shell's national CCS lead Tim Wiwchar told CTV News Edmonton.

"We called it a demonstration project."

Shell is currently planning a CCS project at Scotford that would have a storage capacity of 300 million tonnes of carbon dioxide, or the above-90 per cent capture levels industry says current technology now allows.

The company is expected to decide to move forward or not with Polaris in late 2023.

'A FRACTION OF THOSE EMISSIONS'

Quest cost $1.35 billion, $845 million of which came from the provincial and federal governments. Some of the provincial dollars, contingent Quest's performance, continue to flow in.

And more dollars will flow to similar projects in the future.

Alberta wants to increase its CCS capacity and has incentivized proposals as part of a plan to capitalize on what is expected to become a $2.5-trillion global hydrogen market by 2030. Hydrogen's potential is premised on its nature to burn cleanly. When it is made alongside a carbon capture system, like at Shell Scotford Complex, it's known as blue hydrogen – and considered dirtier only than green hydrogen made with renewable energy.

- Alberta prioritizes oil sands' carbon storage hub, energy minister says

- Plans for $1.3B net-zero hydrogen plant underway in Alberta's capital region

- Alberta hopes hydrogen becomes the next oil sands and 'generational wealth' creator

- Alberta funding $131M in new emission reduction projects

But Eagleton says it is misleading for the fossil fuel industry to present hydrogen production and carbon capture as favourably as it does when CCS can't transform the oil-and-gas sector into a zero-emitting industry.

The senior campaigner at Global Witness found Quest only captured 48 per cent of carbon emissions produced by the Scotford complex – which he called "a fossil hydrogen plant," which Shell disputed – and 39 per cent of all greenhouse gas emissions.

"Trying to apply carbon capture systems to the rest of the world's fossil hydrogen plants could be a disaster for the climate because it might only capture a fraction of those emissions," Eagleton told CTV News Edmonton.

He also believes investing more in carbon-capture infrastructure is a bet in technology that hasn't yet proven itself, when compared to things like wind and solar power.

"It's these options that will take us to a safer climate and not more investment in fossil-fuel infrastructure, which is what fossil hydrogen will entail," Eagleton added.

"Given…that CCS is required in other industries that go beyond fossil fuels -- fertilizer, cement, chemicals, those are all going to be required into the future -- that again, this is a proof point using an oil and gas facility that CCS does work," Wiwchar responded.

"[Quest] has captured over six million tonnes of CO2. That's six million tonnes that would have been emitted from the upgrader…had we not built Quest."

Alberta's energy minister did not respond to CTV News Edmonton's request for comment.

With files from CTV News Edmonton's Touria Izri

CTVNews.ca Top Stories

Spectacular aurora light show to be seen across Canada Friday night

A rare and severe solar storm is expected to bring spectacular displays of the northern lights, also known as aurora borealis, across much of Canada and parts of the United States on Friday night.

Town of Fort Nelson, B.C., ordered to evacuate due to wildfire

The entire town of Fort Nelson, B.C., as well as the nearby Fort Nelson First Nation, has been ordered to evacuate due to an out-of-control wildfire.

Snowbirds in Vancouver for puck-drop flyby as Canucks face Oilers

The Canadian Forces Snowbirds will be performing a flyover across downtown Vancouver at the start of tonight's Stanley Cup playoff game between the Canucks and the Edmonton Oilers.

McGill University seeks emergency injunction to dismantle pro-Palestinian encampment

McGill University has filed a request for an injunction to have the pro-Palestinian encampment removed from its campus.

Which Canadian cities have the highest and lowest grocery prices?

Where you live plays a big factor in what you pay at the grocery store. And while it's no secret the same item may have a different price depending on the store, city or province, we wanted to see just how big the differences are, and why.

Swarm of 20,000 bees gather around woman’s car west of Toronto

A swarm of roughly 20,000 bees gathered around a woman’s car in the parking lot of Burlington Centre.

Video shows naked raccoon catching B.C. family by surprise

When Marvin Henschel spotted a strange and hairless creature wandering through a front lawn in B.C.'s Lower Mainland, he could barely believe his eyes.

Barron Trump declines to serve as an RNC delegate

Former U.S. President Donald Trump's youngest son, Barron Trump, has declined to serve as a delegate at this summer’s Republican National Convention, according to a senior Trump campaign adviser and a statement from Melania Trump's office.

Out-of-control wildfire prompts evacuation alert for Fort McMurray, Saprae Creek Estates Friday night

An evacuation alert was issued for two Wood Buffalo communities Friday night, as crews battled an out-of-control wildfire near Fort McMurray.